View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

View the Specification

We Ship the material with complete protection following the safety data sheet. Our courier service is authentic and responsible for shipment. Also, we are too much concerned about the timely delivery of the product to our customer and therefore maintaining the good relation with the customer.

We produce the best quality of materials. Our material goes through 3 check system to avoid the faulty material delivery to our customer. Also our research and backend team take the complete details of the requirement in order to reduce the low quality materials synthesis.

We're here round the clock, 24 hours a day, 365 days a year. If you need a response immediately, it's best to call us on the phone. We are always connected to the globe with our services. We can be reached 24*7 through our

email-id: sales@technanoindia.com and

(M.) +91-9555163320 (India)

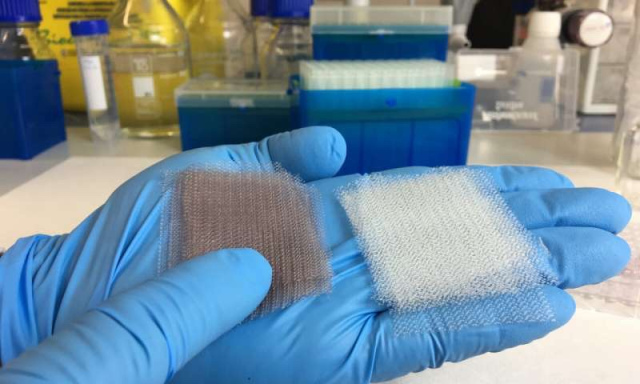

Invented approximately 50 years ago, surgical medical meshes have become key elements in the recovery procedures of damaged-tissue surgeries, the most common being hernia repair. When implanted within the tissue of the patient, the flexible and conformable design of these meshes hold muscles securely and allows quicker recovery than conventional surgical procedures of sewing and stitching. However, the insertion of a medical implant in a patient’s body carries the risk of bacterial contamination during surgery and subsequent formation of an infectious biofilm over the surface of the surgical mesh.

Nanomaterials have the latency to offer often lighter, stronger, and infinitely more durable components as compared to the conventional metals and plastics being currently used in the automotive industry. The blending of nanomaterials and aluminum in the engine could produce a newfangled type of material that will be more robust without compromising on weight.

Nano particles of aluminum can be specifically engineered to create lighter, more powerful, and more efficient engines.

Automobiles in the coming time will be greatly benefitted from nanotechnology and nanomaterials. The worldwide prospect for lower emissions and fuel economy are generating enormous demands for lightweight, robust, and low-cost materials to reinstate costly metals and composites, and nanotechnology can facilitate to congregate those demands. Although nanotechnology has already brought copious outbreak in manufacturing and design of the automobile industry, but still we are only seeing the top of the iceberg on what this novel technology can propose for the potential of automotive manufacturing.

Nanotechnology is at the vanguard of the new generation category of fluids, lubricants, and engine coatings. Nanofluids can provide the ideal size, particle shape, and concentration to offer enhanced lubricity than conventional fluids. This will not only lead to improved protection against heat, but also against friction and wear. Nanoparticles of copper and gold are found to be effectual in developing a new type of liquid protective film to substitute conventional fossil-fuel based oils, making the car engine additional sustainable.

Silicon nanoparticles can be used for next generation lithium-silicon batteries. Nanotechnology is being used to improve the cathode materials in an usual lithium-ion and lithium-polymer battery. Nano-infused batteries in electric vehicles are on their way to propose extending range, comparatively diminutive charging times, and a more environmentally-friendly construction.

Automobile paint layers are among the most susceptible facet of the finish, mostly if exposed to harsh elements. There is a rising requirement for materials which will uphold the paint layer’s appearance for an extended period. Nanosized inorganic fillers can chemically link with the clearcoat molecules to form a flexible and extremely firm coating. This will give the bring a long-lasting shine whilst offering absolute fortification against fading, cracking, and wear.

With a wide range of applications for each feasible part of a contemporary car, nanotechnology seems set to alter vehicle manufacture. Nanomaterials are the promising source to produce cleaner, cheaper, robust, more reliable and sustainable vehicles.

Nanotechnology has the capability to certainly impart a substantial impact on sustainable agriculture and precision farming development. This ultimately aims to maximize agriculture output (i.e., crop yields), while minimizing input (i.e., fertilizers, pesticides, and herbicides) through monitoring environmental variables and applying targeted action.

All of the leading producers of agricultural chemicals are actively researching nanotechnology for use in agriculture.

Nanomaterials like MWCNTs penetrate seeds and increase the germination rate by enhancing the seed water uptake and utilization efficiency of the plants. Silicon, TiO2-, alumina- and copper- NPs have also been suggested as potential candidates for controlling a range of agricultural pests, enhancing plant tolerance of various abiotic and biotic stresses, and improving the performance of plant growth compared to their coarser bulk materials.

Also, nanosensors are being developed as they offer the opportunity to assess crop growth and field conditions including moisture levels, soil pH, fertility and temperature, crop nutrient status and concentrations, as well as early biological alterations induced by stressing stimuli in plants in order to support sustainable agriculture and enhanced productivity.

Nano-formulations can also be used for pesticidal purposes which may offer benefits due to their greater solubility, mobility and durability; the opportunity to reduce the amount of active ingredients used; the possibility to employ products releasing less harmful chemicals to non-target organisms thus reducing the development of resistance; as well as the ability to provide ingredient protection against premature degradation.

Biosolids containing nanosized metals derived from consumer products (i.e., Ag, TiO2, and ZnO-NPs) and employed as land-fertilizers, landfilling and incineration as other methods of biosolid disposal, togetherwith irrigationwithwastewater or contaminated surface water may all be considered as a possible alternative source of nanomaterials into the environment.

Get the latest new about trending and best material properties and quotation directly in your inbox.

| MENU |

|

:: Home :: Products :: Contact Us :: About us :: Services |